Chemical Reaction Engineering Blog Posts

The Use of COMSOL Multiphysics® in the Food Industry

Food for thought: Explore how previously failed products and the use of multiphysics simulation inspire innovation in the food industry.

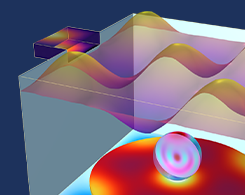

A Practical Sedimentation App for Toxicology Analysis

Sedimentation is widely used in toxicology, biochemistry, and biomedicine. You can study how gravity affects this physical phenomenon with simulation.

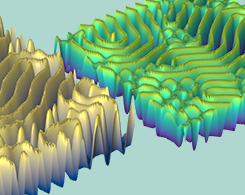

Visualizing the Emergence of Turing Patterns with Simulation

Turing patterns are often found in nature. The conditions behind the emergence of these patterns can be studied with chemical modeling.

Extracting DNA: From Pumpkins to Mammoths

Here, we go over how to recover DNA from a pumpkin using a simple experiment, as well as how scientists made a recent breakthrough in DNA extraction research.

The History and Science Behind Vinyl Records

As vinyl records explode in popularity, we take a look back at the history of records, as well as the interesting science behind how they are produced — and how they play music.

How to Model Metabolic Reaction Networks with COMSOL®

Certain ice creams, puddings, and candies have an extremely vivid yellow color that comes from vitamin B2. The manufacturing of this supplement is one example of a metabolic reaction network…

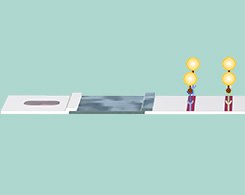

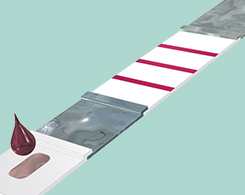

Modeling a Rapid Detection Test in COMSOL Multiphysics®

Curious about how exactly the rapid detection tests for COVID-19 work? Get a comprehensive explanation here, as well as 3 example models in COMSOL Multiphysics®. (Part 2 of 2)

An Introduction to the Physics of Rapid Detection Tests

Rapid detection tests based on lateral flow assay (LFA), also called immunochromatographic tests, can be thought of as quite advanced, yet very robust, microlaboratories. (Part 1 of 2)