Micromechanics and Macromechanics of a Composite Cylinder

Application ID: 67001

Fiber composites are widely used in industrial applications. Compared to more traditional metallic engineering materials, fiber composites often have superior specific stiffness and strength properties, and they are often more corrosion resistant. Also, properties like strength, stiffness, and toughness can often be tailored to specific applications. A fiber composite consists of load carrying fibers embedded in a polymer resin. The composite material is typically a laminate of individual layers, where the fibers in each layer are unidirectional. This model demonstrates how to perform a stress analysis of a laminated composite cylinder.

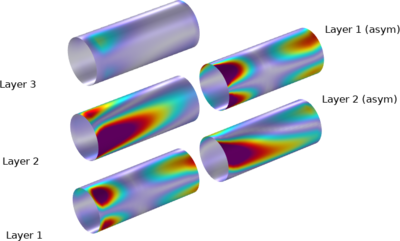

Modeling individual fibers in every layer in the laminate is unfeasible. A simplified micromechanics model of a single carbon fiber in epoxy is instead used to estimate the homogenized elastic properties of a single layer. These properties are then used in the macromechanical model of the laminated composite cylinder. Two approaches are used to model the laminate, namely the Layerwise (LW) theory and the Equivalent Single Layer (ESL) theory.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Specification Chart and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.