Analysis and Comparison of Modeling Approaches for Heat Pipes

A novel injection molding tool temperature control system based on heat pipes is being researched at the Bielefeld University of Applied Sciences and Arts (HSBI). This temperature control technology offers great potential for improving product quality and saving energy in the production process. Heat pipes have a hermetically sealed and evacuated working chamber containing a working fluid (distilled water), which serves as a highly efficient heat transfer medium (latent heat) in a thermodynamic cycle (evaporation and condensation).

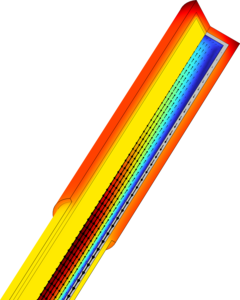

The latent heat transfer occurs through the vapor flow inside the heat pipe working chamber, which can be described by the physical state variables of flow velocity, pressure, temperature, and density. These physical state variables are difficult to measure, so it is of interest to approximate the basic functioning of the thermodynamic heat pipe cycle process through numerical simulation and determine the physical state variables approximately.

The heat pipe cycle process model is built in the simulation software COMSOL Multiphysics® based on the modeling approaches available in the Application Library (ID 43841 and 90311). Both approaches are projected onto the geometry of a heat pipe for which relevant thermodynamic parameters (boiling temperature, saturation pressure, heat energy transfer rate) are measured experimentally. The modeling must represent the thermodynamic cycle process, which is divided into four continuously running process steps: evaporation, vapor flow, condensation, and liquid flow. In addition, the temperature- and pressure-dependent physical properties of the working fluid (saturation temperature and pressure, density, evaporation enthalpy) and the interaction between heat transfer and vapor or liquid flow must be considered.

The simulation results for temperature, pressure, and flow velocity are analyzed and evaluated. It is found that the basic functioning of the thermodynamic heat pipe cycle process is represented by the simulations. It should be noted that a high accuracy of temperature- and pressure-dependent fluid properties (saturation temperature and pressure, density, evaporation enthalpy) is necessary for modeling vapor flow inside the heat pipe working chamber. Comparing the simulation results with the experimentally measured data allows calibration of the simulation model at the operating point under consideration and thus the approximate determination of the physical state variables inside the heat pipe working chamber.

A more detailed modeling of the heat pipe cycle process requires an extension of the model to include the evaporation and condensation processes, as well as consideration of the initial conditions (temperature, pressure and fluid fractions in the heat pipe working chamber).

Download

- Paper_Modeling_Approaches_for_Heat_Pipes.pdf - 0.98MB

- Fromme_5901_poster.pdf - 1.01MB