Multiphysical Study of Copper Laser Welding Process Stability Using the COMSOL® Application Builder

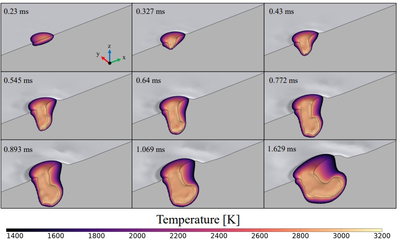

A numerical model of laser welding process applied on highly optically reflective and thermally conductive materials such as copper has been developped. The latter considers multiphysical couplings of CFD, heat transfers and phase-field representation to account for topological deformation of the liquid-gas interface. In addition, a dedicated JAVA® method has been setup thanks to COMSOL® Application Builder to implement a new coupling between phase-field description and geometrical optics, allowing self-consistent computation of the well-known « beam trapping effect » in laser processes. Hence, heat source induced by laser-matter interaction is updated correspondingly to liquid-gas interface fluctuations. Moreover, an adaptative mesh refinement (AMR) method is considered to conteract the high numerical complexity of such a model. Numerical results are compared to x-ray measurements of keyhole dynamic formation.

Download

- Paper COMSOL Conference 2023 V3.pdf - 0.7MB

- Daligault_5451_poster.pdf - 1.13MB