Simulating the Effect of a Change in Deposit Geometry on the Performance of a Soluble Lead Flow Cell

Introduction

The soluble lead flow battery (SLFB) is a form of redox flow battery (RFB), an electrochemical device where energy is stored in a liquid electrolyte. The electrolyte is pumped around a flow circuit from a reservoir to the cell where redox reactions occur and the energy is recovered. The electrolyte then returns to the reservoir. Typically in RFBs, there is no phase change and all active species remain dissolved in the electrolyte. However, in the SLFB, solid Pb and PbO2 form at the negative and positive electrode respectively during charge. Dissolution of both deposits occurs during discharge. RFBs are typically for large scale energy storage, i.e. >MW scale for several hours. Previous models of the SLFB have assumed the thickness of the solid deposits to be small [1-4]. However, at the high energy requirements for large scale energy storage, the thickness of these deposits becomes significant.

The use of COMSOL Multiphysics® software

A two-dimensional, time-dependent model that simulates the operation of the soluble lead flow cell is produced. Unlike previous models, this work simulates a change in geometry due to the growth of solid deposits at the electrodes. The model includes a solid domain for the positive and negative electrodes and a fluid domain for the electrolyte. The remainder of the flow cell, including the reservoir and the flow-circuit, is not explicitly modeled. The flow of electrolyte is simulated using the laminar flow module. The electrolyte reservoir is assumed to include perfect mixing. This is implemented by using ordinary differential equations using the Global ODEs and DAEs interface. The transport of species in the electrolyte, the kinetics, and the voltage profile are simulated using the Tertiary Current Distribution, Nernst-Planck interface.

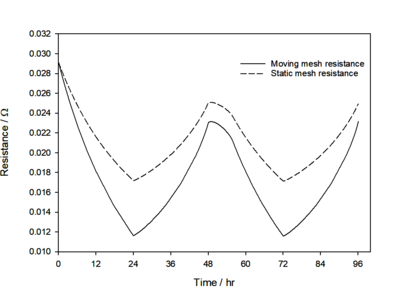

As Pb and PbO2 are deposited onto and stripped from their respective electrodes, the effective inter-electrode gap and hence the flow rate decreases and increases again respectively. Further to this, the change in electrode deposit geometry will also change the resistance of the cell. The geometry change is implemented using the Deformed Geometry physics interface.

Results

A significant difference to the resistance of the cell is made when the thickness of the deposits are included. The resistance of the cell over its operation is shown to be significantly different when the geometry of the deposits are modeled. As such, there is a resulting change in the voltage profile. The flow rate also changes as the geometry changes. These results, therefore, show that for a high energy SLFB, the change in geometry of the deposits is significant when modeling the SLFB.

References

[1] M.N. Nandanwar and S. Kumar, Journal of The Electrochemical Society, vol. 161, no. 10, pp. A1602-A1610, 2014.

[2] A.A. Shah, X. Li, R.G. Wills, and F.C. Walsh, Journal of The Electrochemical Society, vol. 157, no. 5, pp. A589-A599, 2010.

[3] A. Oury, A. Kirchev, and Y. Bultel, Journal of Power Sources, vol. 246, pp. 703-718, 2014.

[4] A. Bates, S. Mukerjee, S.C. Lee, D.H. Lee, and S. Park, Journal of Power Sources, vol. 249, pp. 207-218, 2014.