The Effect of Aluminum Content on Convective Flow of Molten Metal Generated by Arc Plasma

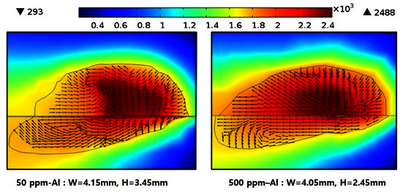

Arc plasma can heat and melt the metal material and flows of molten metal can be affected by several forces such as Lorentz force which is ruled by current, Marangoni force controlled by surface tension, buoyancy force, and arc drag force. Usually, surface tension variation is determined by the composition of materials. The most known is that the surfer content has a significant effect on the change in surface tension, thereby velocity and direction of Marangoni flow can be changed by such small ingredient in steel plate. Also, aluminum contents can affect the surface tension coefficient indirectly by forming an intermetallic compound with oxygen. In this study, the variation of molten metal flow is simulated with the variation of aluminum content in stainless steel material. Because it is very hard to observe the flow characteristics of the molten metal, simulation is very useful to investigate the flow status inside of molten pool boundary. Furthermore, in order to understand the action of molten metal generated by heating of arc plasma, multi-physics problems should be solved with mass conservation, momentum conservation and energy conservation equation. We used several different modules including heat transfer module, CFD module and AC/DC module of COMSOL Multiphysics. The used physics were laminar flow, heat transfer in solids, electric currents, magnetic field and multiphysics with Lorentz force. It was very complicated because of many physics and high temperature variation. Therefore mesh control and appropriate variation of material properties according to temperature were the most important to get the meaningful converged results. As a conclusion, in case of 50 ppm of aluminum content, an inward direction was generated in the molten pool. On the other hand, we can confirm that outward direction flow is dominant over than 350 ppm of aluminum. These are very useful results to fabricate the new steel alloy material including aluminum in terms of welding characteristics. We can guide the amount of aluminum content in steel alloy material based on these simulation results of molten metal flow.

Download

- cho_poster.pdf - 1.12MB

- cho_abstract.pdf - 0.08MB