Traveling-wave Microwave Reactor

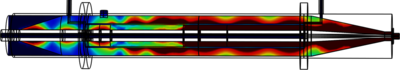

The significance of electrification of industry increases with the growing influence of renewable electricity as a primary energy source on earth. In this sense, microwave heating is a well-established electricity-based and market-mature technology employed on the commercial scale in various applications, such as drying, thawing, pasteurization, sintering, and ceramic processing. However, commercial implementation of the microwave heating in chemical reactors are non-existent due to its non-uniformity on heating. This is due to the complexity of the interaction between microwaves and solid catalysts, as well as to several important design factors influencing the performance of microwave-assisted reactor. In order to provide highly uniform heating, a novel reactor concept has been developed based on a coaxial waveguide structure, the so-called, Traveling-wave Microwave Reactor, TMR. In this manner, a three-dimensional finite element model has been developed using the COMSOL Multiphysics® simulation environment. Heat Transfer, RF and CFD modules have been coupled to solve energy, heat, momentum equations together with Maxwell’s electromagnetic field equations. The developed and constructed TMR has an annular reaction zone between two concentric quartz cylinders inside the waveguide giving a 0.232 liter of accessible volume. The model has been validated from the electromagnetic and heat transfer points of view. To do that, silicon carbide extrudes have been used as catalyst support and microwave absorbing media in the packed-bed configuration. The temperature evolution of the packed-bed showed the same trend as the one observed experimentally with only an average deviation of less than 9%. For further optimization of the TMR, different packed-bed parameters such as diameter, length, and position inside the reactor have been studied in the validated model. Simulation and experimental results prove that the uniform temperature distribution is possible in the TMR. Moreover, heating characteristics of different catalysts and catalyst supports in the designed reactor are under investigation. It is envisaged that this particular reactor concept may enable process scale-up while giving temperature homogeneity beyond the intrinsic restrictions of cavity systems.

Download

- 136_-_Traveling-wave_Microwave_Reactor.pptx - 122.87MB