Induction Heating

The Induction Heating Process

Induction heating is similar to the Joule Heating Effect, but with one important modification. The currents that heat the material are induced by means of electromagnetic induction; it is a noncontact heating process.

An induction coil above a conducting material (copper plate).

An induction coil above a conducting material (copper plate).

By applying a high-frequency alternating current to an induction coil, a time-varying magnetic field is generated. The material to be heated, known as the workpiece, is placed inside the magnetic field, without touching the coil. Note that not all materials can be heated by induction, only those with high electrical conductivity (such as copper, gold, and aluminum, to name a few). The alternating electromagnetic field induces eddy currents in the workpiece, resulting in resistive losses, which then heat the material up.

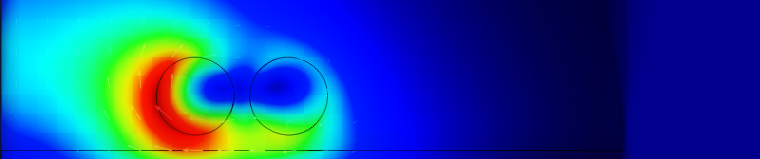

Induced current density in a copper plate at 10 Hz.

Induced current density in a copper plate at 10 Hz.

Induced current density in a copper plate at 10 Hz.

Induced current density in a copper plate at 10 Hz.

Furthermore, the high frequency leads to a skin effect. The alternating current is forced to flow in a thin layer toward the surface of the workpiece. This in turn leads to an increased resistance of the conductor, ultimately resulting in a greatly increased heating effect.

Ferrous metals are heated by induction more easily than other materials. This is because their high permeability boosts the induced eddy currents and skin effect. In addition, another heating mechanism occurs. The material's iron crystals are magnetized and demagnetized over and over by the alternating magnetic field. This causes the magnetic domains to flip rapidly back and forth, leading to hysteresis losses, which result in additional heat.

Induction Heating in Design

So, induction heating takes place without physical contact between the workpiece and induction coil. This lends it to processes where a high degree of cleanliness is paramount, such as in semiconductor manufacturing, for example.

Additionally, this method of heating is very efficient, as the heat is generated inside the workpiece, as opposed to somewhere else and then applied to the workpiece. In other words, with induction heating, we can avoid heat losses from the surfaces that would provide the electrical connection, thus improving the overall heating efficiency.

Induction heating involves two different types of physics: electromagnetism and heat transfer. Some material properties are temperature dependent, meaning they change when heat is applied. In that event, you can consider the two physical phenomena coupled.

Skin effect: The current density is high near the surface of the conductor.

Skin effect: The current density is high near the surface of the conductor.

Skin effect: The current density is high near the surface of the conductor.

Skin effect: The current density is high near the surface of the conductor.

Designs that Leverage Induction Heating

One innovation that takes advantage of induction heating is the induction stove. In this design, the coil is placed beneath the stove top and its electromagnetic fields act on the metal pot. Since only highly conductive materials can be heated this way, the pot heats up, while if you placed your hand on the stove top, it would not feel hot.

The semiconductor industry also makes use of this process for heating silicon. Other applications include sealing, heat treatment, and welding, to name a few.

Temperature plot: Induction heating in a copper cylinder

Temperature plot: Induction heating in a copper cylinder

When Heating Leads to Wasted Power

While there are plenty of products and processes that function thanks to induction heating, there is one application where heating leads to wasted power. When it comes to transformers, it is important not to allow eddy currents to flow inside the cores. If eddy currents heat the transformer's magnetic core, power is wasted and further problems could occur, such as structural damage.

Published: November 6, 2014Last modified: February 21, 2017